Peter Grubb was searching for a source of building stone in the mid 1700s. What he discovered was the richest deposit of iron ore in the western hemisphere. It continued to produce ore for a variety

of companies until it was eventually closed by Bethlehem Steel in 1976. By this time the famous deposits of the Mesabi Range were discovered and those of Cornwall PA were no longer commercially viable to

recover.

Cornwall Furnace stands nearly intact today as it was in the 1700s

when it was built. It is the most complete example of the early iron blast

furnaces

from Colonial America.

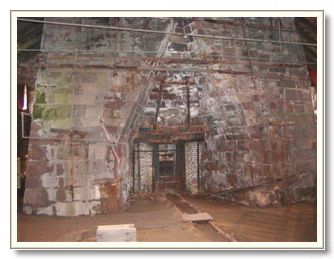

Coke and Ore Storage Bins

This is the working end of the Furnace. The molten iron is tapped here and it flows

along the trough in the floor to molds, or "pigs" buried in

the sand of the floor. Hence the term,

Pig Iron.

This 24-foot diameter wheel was turned, originally by water power, and

later by steam, generated from the heat of the blast, to operate air pistons to

force air to the furnace.

An old road sign pointing to the site.

The middle part of the picture shows the exterior of the blast

furnace. It is 30 feet high and can be

accessed at top to load the ore, coke and limestone, and at the bottom to

remove the slag and molten iron.

Molten iron flows through this trough to the pigs in the floor.

This is the Paymaster's house which sits close to the furnace. A welcome site to the workers whose 12 hour

shifts and only 2 days off per month earned very little for their toil.

This steam engine replaced the water wheel to operate the air pumps

for the blast. It is powered from the black

pipe which carries steam generated by the excess heat of the furnace.

The original wooden axle of the Great Wheel was bent by the weight of

the wheel from sitting idle for many years when the state took over the

site. A rebuilt axle is in place to

allow the Great Wheel to rotate today.

No comments:

Post a Comment